Maintenance, Cleaning and care, Troubleshooting – Parkside PDMT 6.2 A1 Benutzerhandbuch

Seite 41

41

GB

Commissioning / Possible applications / After initial use

After initial use / Maintenance / Cleaning and care / Troubleshooting

Be careful when putting down

the device. Always put down the equipment so

it does not come into contact with the trigger.

This could potentially result in accidental activa-

tion of the equipment, which again could result

in hazards.

Maintenance

ATTENTION! All maintenance must be per-

formed by trained individuals. Following the

specified maintenance instructions ensures a

long service life and proper operation of this

quality product.

Disconnect equipment from the compressed air

source when performing maintenance and care.

Check the condition of wear and tear items

and accessories with every maintenance.

Note: Daily cleaning and regular lubrication

are absolutely required for smooth operation.

Only use special tool oil.

No maintenance is required beyond the above

mentioned lubrication and cleaning.

Cleaning and Care

Only use a dry cloth to clean the multitool.

Never clean with liquids such as petrol, sol-

vents or water.

Do not allow liquids to enter the equipment.

Use a vacuum cleaner to remove abrasive dust

or sawing debris from the equipment.

For oiling you may use one of the follow-

ing options

Note: If available, you may use an in-line a line

oiler, -trap or an entire maintenance unit as shown

above. We highly recommend using such mainte-

nance accessories.

a)

via oil-mist lubricator

A complete maintenance unit includes an oil-mist

lubricator and is attached to the compressor

b)

via line lubricator

A line lubricator is installed within close proxim-

ity of the tool (approx. 50 cm away) which ad-

equately supplies the equipment with oil.

c)

manually

If your equipment (or your compressed air sys-

tem) features neither a maintenance unit nor a

line lubricator you must add 3–5 drops of oil

to the compressed air connection before each

use. If the air tool has not been used for several

days you must add 5–10 drops of oil to the

compressed air connection before powering

on the equipment.

Always store your air tools / equipment and ac-

cessories in dry locations.

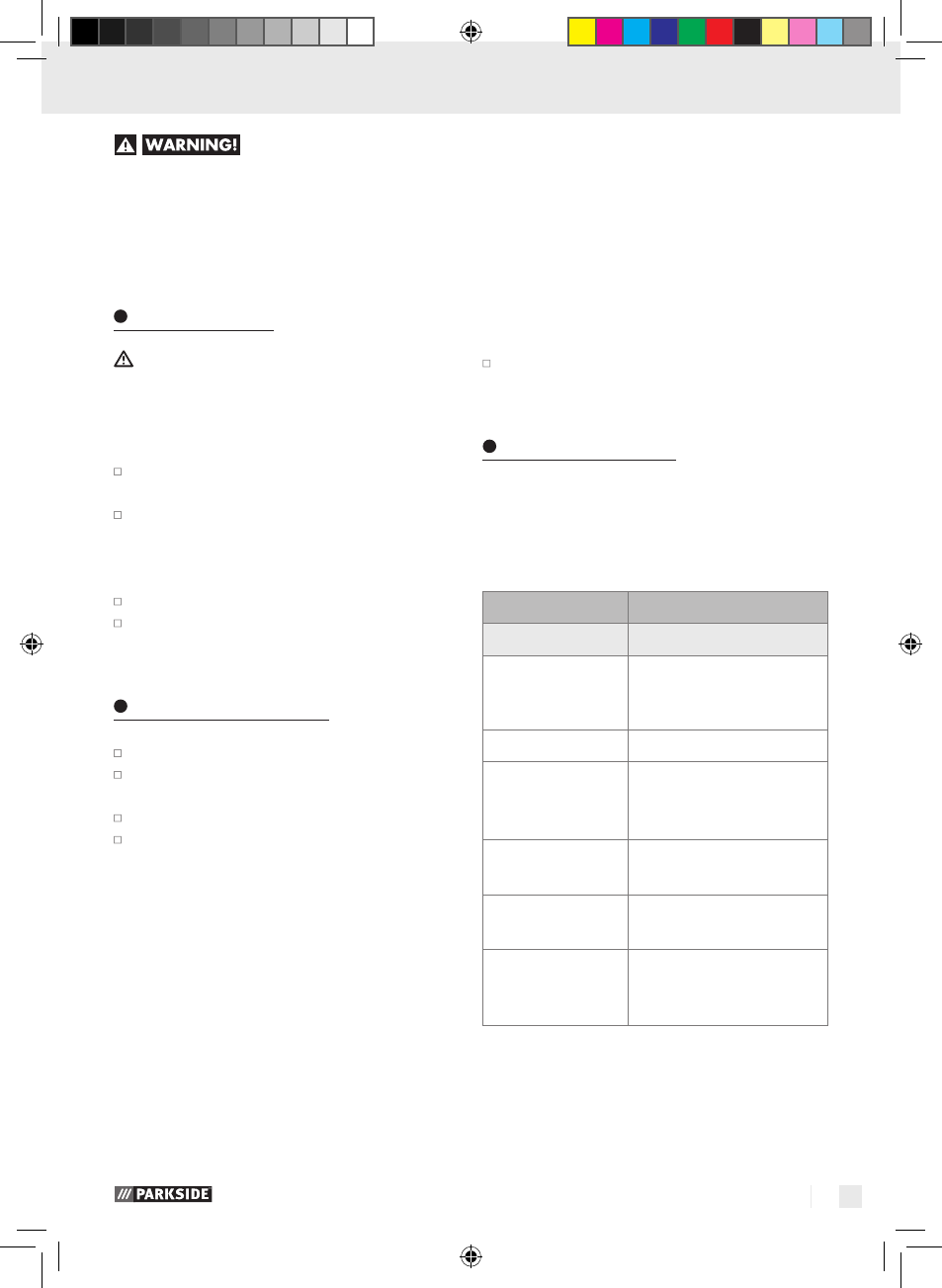

Troubleshooting

Note: Regular lubrication is imperative to ensure

the longest possible life for your compressed air de-

vice. We recommend continuous lubrication via in-

line oil-mist equipment.

Fault

Reduced performance

Cause

Solution

1. Insufficient pres-

sure

Check all connections and

verify your compressor is

supplying sufficient pressure.

2. Clogged line

Clean the line.

3. Improper lubri-

cation or insufficient

lubricant

Lubricate equipment as in-

structed.

4. Blunt or dam-

aged accessory

Replace accessory.

5. Leak / Leaking

connection

Use teflon tape or replace

the defective part.

6. Contaminated

mechanism

Have your equipment

cleaned by a qualified

technician.

73791_Druckluft-Multitool_content_LB1 (nur NL).indd 41

11.05.12 17:56