2 cleaning the fixture, 3 software update, 4 verifying electronic devices – JB-Lighting Sparx 10 Benutzerhandbuch

Seite 57

- 57 -

10

Zoom & focus:

The zoom effect in all Sparx10 is calibrated at the factory. But if necessary it is possible to fine-

tune the zoom using the ZOOM OFS command.

To ensure a long and satisfying performance of the fixture, check function of the fans in the

head and in the base from time to time. Most important: make sure that there is no dust or fluff

covering the louvers. To clean the fixture open the head cover and the baseplate. Use a brush

and a vacuum cleaner to remove dust and fluff. Don´t damage or bend any parts. Incompetend

performance of the maintenance will invalidate the warranty claims. Consult qualified service

technicans!

RECEIVESOFT

Use the RECEIVE SOFT command to prepare the Sparx10 for a software upload. See 6.3 soft-

ware update and the uploader device documentation.

6.2 Cleaning the fixture

WARNING: Disconnect fixture from mains, and allow unit to cool down for at

least 10 minutes! With direct view on the beam source use a welding

goggle of reduction 4-5!

ATTENTION: Débranchez l‘appareil du secteur et le laissé refroidir au moins 10

minutes! Lors d‘un regard direct dans la source lumineuse il est

fortement recommandé de porter une lunettes de soudeur équipée

de verres à vision atténué degré 4-5!!

!

!

6.3 Software update

6.4 Verifying electronic devices

To update the fixture via PC/Notebook, a upgrade dongle (USB/DMX converter) with software is

required. The upgrade dongle has to be connected to the fixture with a 5 pin XLR connector. The

software for the products is available from the JB-Lighting homepage at

www.jb-lighting.de.

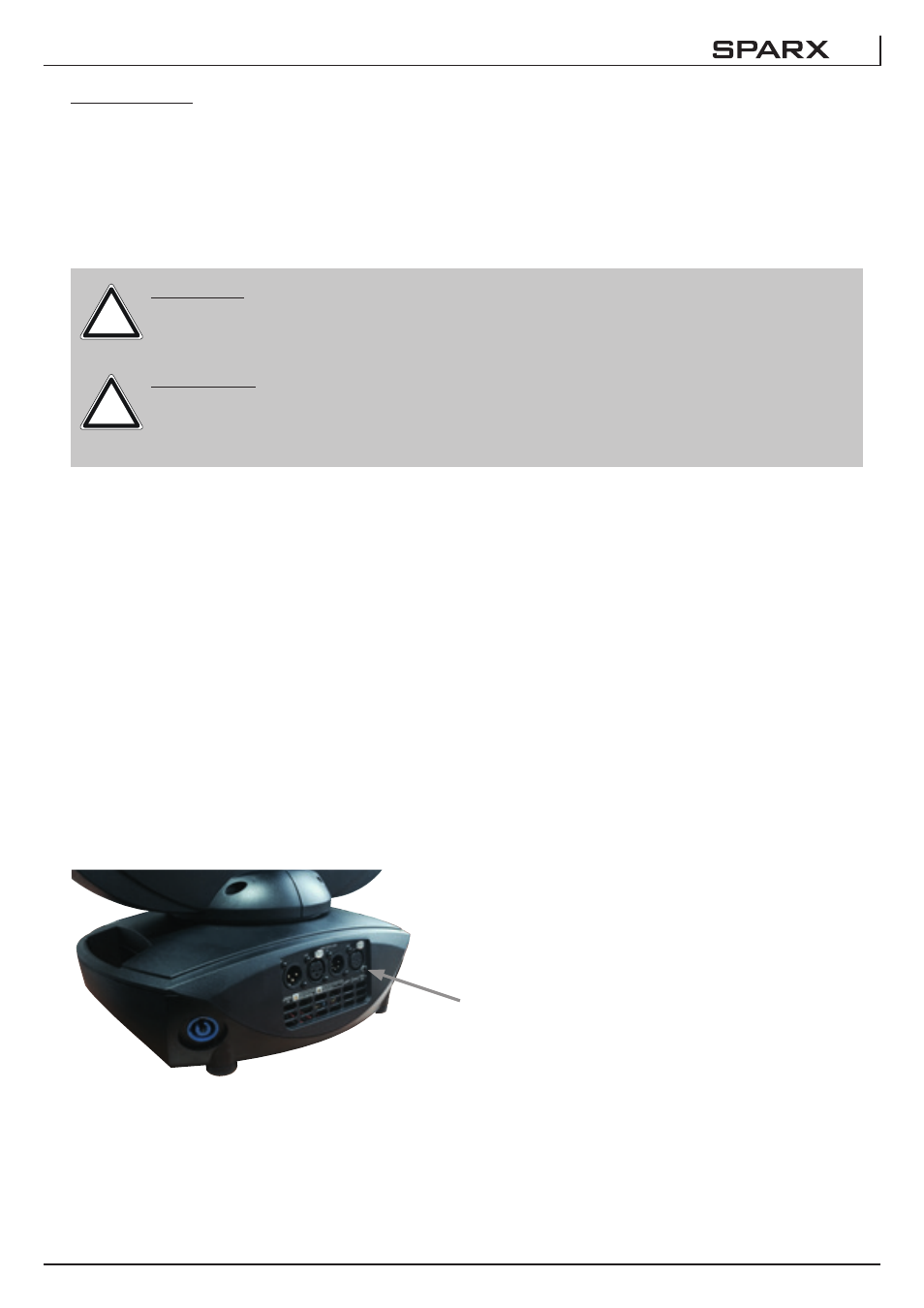

In accordance with the applicable German safety regulations (Accident Prevention and Insuran-

ce, BGV A2/A3), electrical installation and equipment have to undergo inspection at regular in-

tervals. For this purpose, the fixing screw of the 5-pin DMX socket may serve as measuring point

for the insulation and fault current measurement. This screw is connected to all sheet metal parts

by means of a contact disc.

PE - measurement point