Start-up, Start-up / cleaning, care and storage / warranty, Flexible shaft – Parkside PFBS 160 A1 Benutzerhandbuch

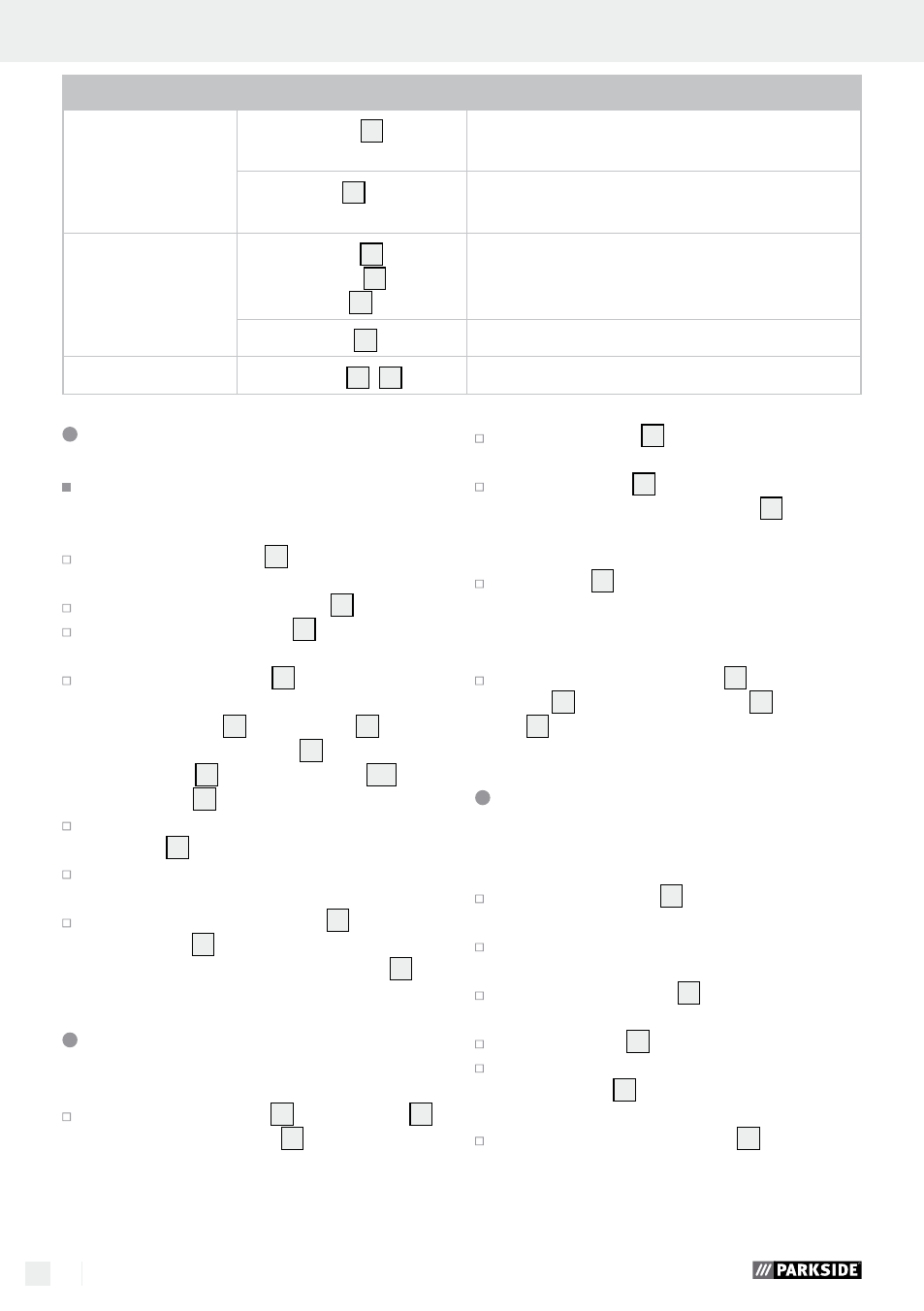

Seite 14: Base assembly

14 GB/IE/CY

Start-up

Function

Accessory

Application

Cleaning

Plastic brushes

30

e.g. cleaning hard to reach plastic housings or

cleaning the area around a door lock

Metal brush

31

e.g. rust removal (see Fig. E)

(The metal brush is softer than steel)

Grinding

Grinding discs

21

Grinding stone

23

,

Grinding bits

20

Grinding stone, detail work on hard materials such

as ceramics or alloy steel (see Fig. G)

Sanding belts

24

Sanding wood

Cutting

Cutting discs

18

,

19

Processing metal, stone (see Fig. H)

Flexible shaft

Never use the spindle lock with the motor on.

The tool or the flexible shaft could otherwise

be damaged.

Unscrew the union nut

5

from the tool, turning

counter-clockwise, and put aside.

Press and hold the spindle lock

8

.

Unscrew the clamping nut

6

from the tool,

turning counter-clockwise.

Attach the flexible shaft

13

to the tool, inserting

the inner axle on the flexible shaft along with

the clamping nut

6

into the collet

7

.

Use the combination wrench

33

to first tighten the

clamping nut

6

, then the union nut

13 b

of the

flexible shaft

13

to the tool, turning clockwise.

Now insert the accessory you wish to use into

the collet

7

of the flexible shaft.

To lock the spindle, slide back the black sleeve

on the flexible shaft.

Using the combination wrench

33

, open the

collet holder

14

on the flexible shaft, insert the

accessory and tighten the collet holder

14

.

Stretch stand for the multi-func-

tion tool (Fig. I)

Screw the stretch stand

16

into the clamp

17

.

Note: The stretch stand

16

can be screwed

into the clamp in two different positions, de-

pending on the whether you‘re attaching to a

horizontal or vertical surface.

Secure the clamp

17

at the edge of a work-

bench or a work table no thicker than 55 mm.

The stretch stand

16

is height adjustable. Loosen

the upper tube of the stretch stand

16

by turning

to the left (–). Extend the tube to the maximum

height and secure by turning to the right (+).

The holder

15

is also height adjustable, simple

turn the black thread to the left. After adjusting

the holder to the correct height, turn the thread

in the opposite direction to tighten.

Secure the tool to the holder

15

of the stretch

stand

16

with the metal bracket

3

. This hold-

er

15

rotates by 360°.

Base assembly

Using the attachment, the tool is particularly suited

for cutting special shapes (holes for sockets, etc.).

Attach the milling bit

27

as described in chapter

„Attaching / changing the tool / collet“.

Ensure that the bit’s shaft protrudes from collet

by approx. 13 mm.

Unscrew the union nut

5

from the tool, turning

clockwise, and put aside.

Screw the base

12

onto the unit.

To set the correct working depth, loosen the

locking screw

11

and adjust the bottom of the

base assembly to the desired size.

Then tighten the locking screw

11

.

Start-up / Cleaning, care and storage / Warranty