0 maintenance – Flowserve GZV 10 Benutzerhandbuch

Seite 3

GESTRA GmbH

Datum/Date:

2001

-09-18

Seite/Page:

3

Unterlagen-Nr./Dokument No.:808535

Für diese Unterlage behalten wir uns alle Rechte vor / All rights reserved - System: Word 97 für Windows

3.0 Maintenance

3.1 We recommend to check the valve at regular intervals.

3.2

The valve is equipped with a PTFE seal located at the valve cone. If the shut-off of the valve is

untight, the cone seal is defective and has to be replaced or reconditioned. To change the

cone seal proceed as follows:

- Depressurize valve

- Undo body screws

- Detach yoke

- Remove force-fitted seal from cone

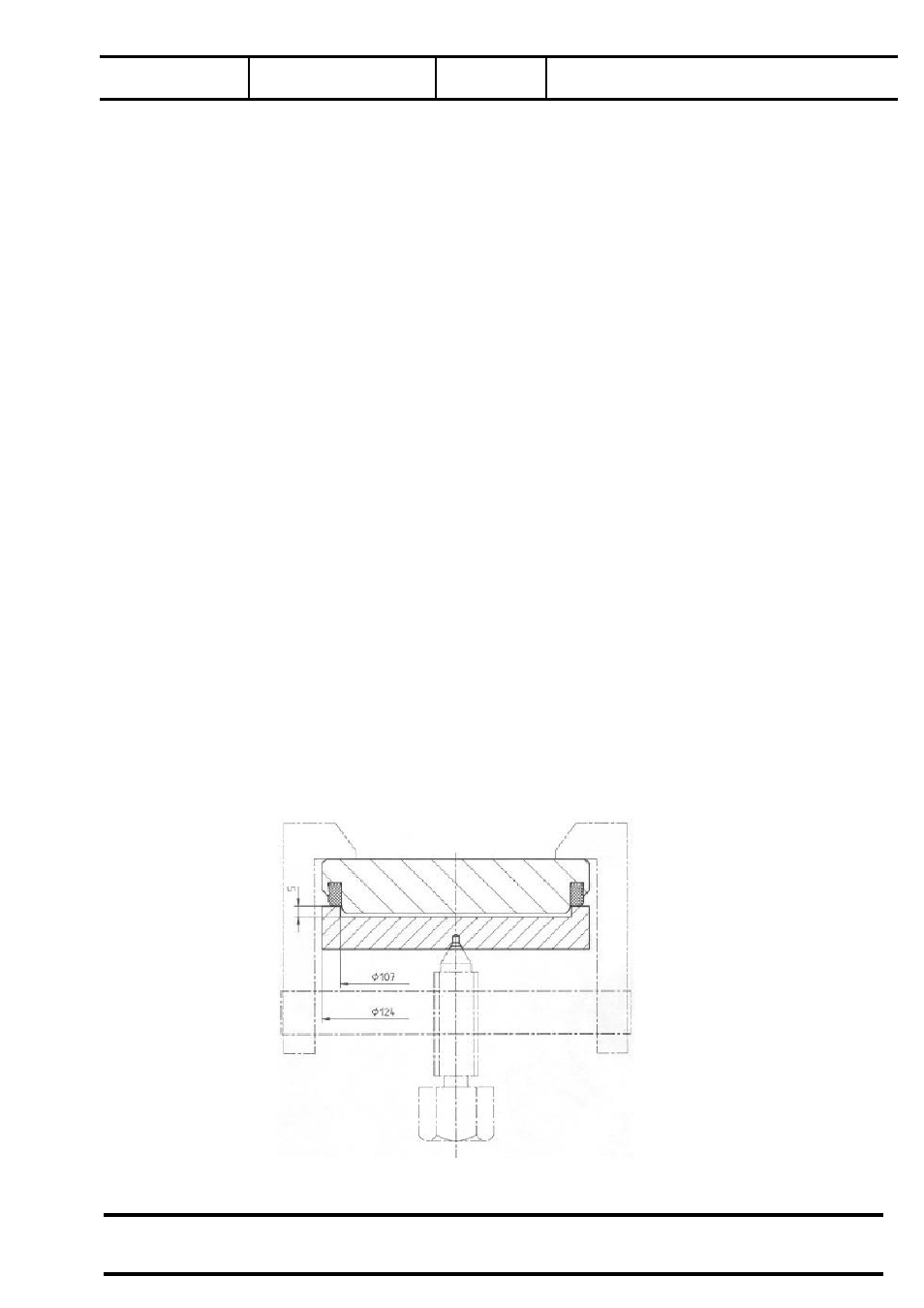

- Carefully and slowly insert new cone seal into the dovetail groove by using a pressing-on

plate as shown in the following drawing

- Make sure that the seal fits tightly in the cone without allowing any play when moving the

cone by hand

- Re-attach yoke with new seal inserted and tighten body screws

- Close valve for 24 hours as tightly as possible in order to adapt the seal to the outline of the

body and the cone

- Check valve for external leakproofness and, after repeated operations, for tight shut-off

3.3

The maintenace-free spindle sealing it provided by a spring-loaded seal and an O-ring. To

change the spindle sealing proceed as follows:

- Depressurize valve

- Undo body screws

- Detach yoke

- Remove handwheel

- Pull spindle out by turning it downwards

- Remove star ring (item 37), star ring support (item 7) and seals

- Clean spindle and yoke seating surfaces

- Insert new seals

- Re-attach yoke with new seal inserted and tighten body screws

- Check valve for external leakproofness and, after repeated operations, for tight shut-off