E.max, Crystallization parameters – Ivoclar Vivadent IPS e.max CAD Chairside v.1 Benutzerhandbuch

Seite 103

51

The following notes should be observed for the crystallization of IPS e.max CAD:

– Carry out the crystallization in a Programat CS or another Ivoclar Vivadent ceramic furnace using the indicated

parameters.

– If you would like to use other, untested ceramic furnaces, please consult Ivoclar Vivadent about their compatibility with

IPS e.max CAD.

– Basically, the following applies:

Ceramic furnaces without

– function for controlled (long-term) cooling

– vacuum function

cannot be used.

– Before the first crystallization and every six months after that, the ceramic furnace must be calibrated.

– Depending on the mode of operation, more frequent calibration should be required. Follow the instructions for the

manufacturer.

The following aspects should be observed for conducting the crystallization:

– Use only IPS Object Fix Putty or Flow as an auxiliary firing paste.

– IPS e.max CAD restorations must not be directly placed on the IPS e.max CAD Crystallization Tray and Pins, e.g. without

auxiliary firing paste, for crystallization.

– Use only the IPS e.max CAD Crystallization Tray and the corresponding IPS e.max Crystallization Pins, since they store the

heat necessary for slow and above all tension-free cooling of the glass-ceramic.

– Always conduct the crystallization under vacuum.

– Always allow the restoration to cool to room temperature after crystallization before further processing.

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic signal of the

furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.

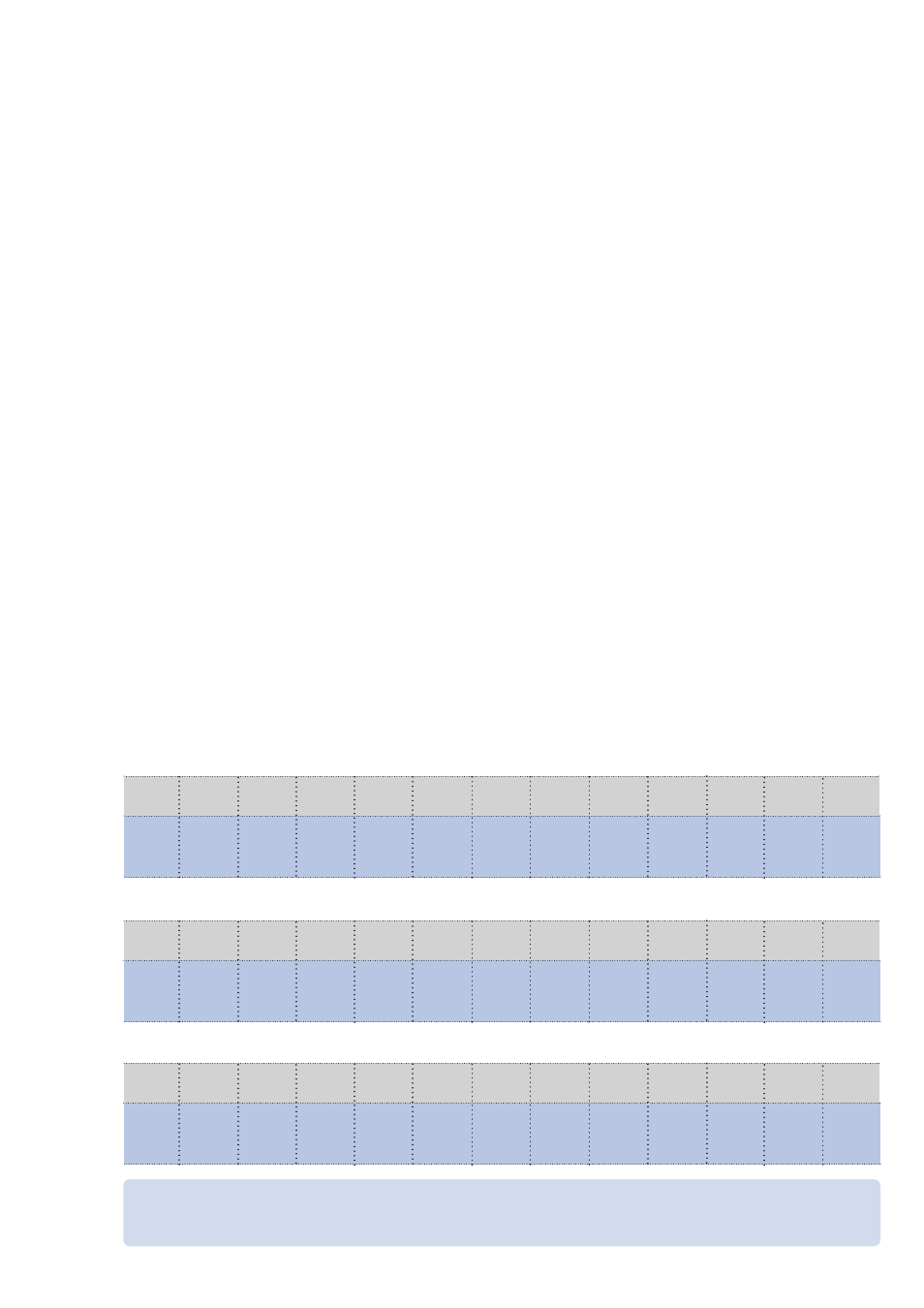

e.max

®

CAD

–

Crystallization Parameters

IPS

Furnace

Programat

CS

Program 3

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

1:30

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding time

H

1

[min]

0:10

Heating rate

t

2

[°C/°Fmin]

30/54

Firing

temperature

T

2

[°C/°F]

840/1544

Holding time

H

2

[min]

7:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C7°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Furnace

Programat

CS

Program 1

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

6:00

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding time

H

1

[min]

0:10

Heating rate

t

2

[°C/°F/min]

30/54

Firing

temperature

T

2

[°C/°F]

840/1544

Holding time

H

2

[min]

7:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C/°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Speed Crystallization/Glaze Spray (at most 2 Restaurationen with Glaze Spray)

Crystallization/Glaze (at most 6 restorations)

Furnace

Programat

CS

Program 2

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

6:00

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding time

H

1

[min]

0:10

Heating rate

t

2

[°C/°F]

30/54

Firing

temperature

T

2

[°C/°F]

840/1544

Holding time

H

2

[°C/°F]

3:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C/°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Correction firing

Please note:

– If glaze paste is used, Speed Crystallization/Glaze Spray must not be used.

– Both Speed Crystallization and Crystallization/Glaze are not suitable for the crystallization of IPS e.max CAD MO.