Ivoclar Vivadent IPS e.max CAD Chairside v.1 Benutzerhandbuch

Seite 84

32

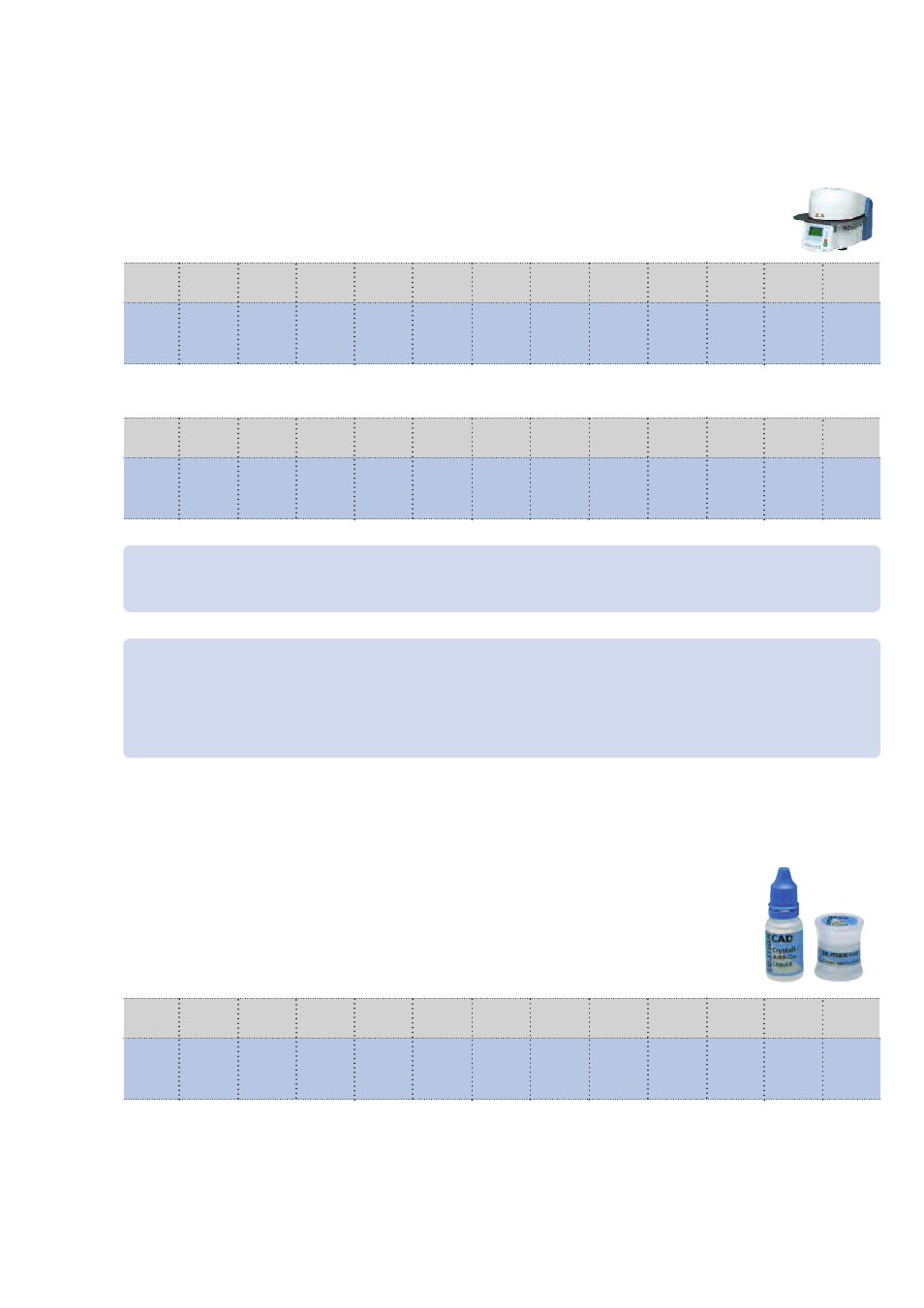

Select the firing parameters in accordance with the number of restorations and carry out the firing in a ceramic furnace

(e.g. Programat CS) using the following parameters.

If additional characterizations or adjustments are required after crystallization, a corrective firing using

IPS e.max CAD Crystall./Shades, Stains and Glaze can be conducted. Conduct the corrective firing also on the

IPS e.max CAD Crystallization Tray.

For minor shape adjustments (e.g. proximal or occlusal contact points), IPS e.max CAD Crystall./Add-On is available.

The adjustments may be made with Speed Crystallization, Crystallization/Glaze and Corrective Firing. The detailed

procedure is described on page 36.

Furnace

Programat

CS

Program 3

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

1:30

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding time

H

1

[min]

0:10

Heating rate

t

2

[°C/°Fmin]

30/54

Firing

temperature

T

2

[°C/°F]

840/1544

Holding time

H

2

[min]

7:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C7°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Furnace

Programat

CS

Program 1

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

6:00

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding time

H

1

[min]

0:10

Heating rate

t

2

[°C/°Fmin]

30/54

Firing

temperature

T

2

[°C/°F]

840/1544

Holding time

H

2

[min]

7:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C/°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Speed Crystallization/Glaze Spray (at most 2 restorations with Glaze Spray)

Crystallization/Glaze (at most 6 restorations)

Furnace

Programat

CS

Program 2

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

6:00

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding time

H

1

[min]

0:10

Heating rate

t

2

[°C/°F/min]

30/54

Firing

temperature

T

2

[°C/°F]

840/1544

Holding time

H

2

[min]

3:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C/°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Correction firing

Please note:

– If glaze paste is used, Speed Crystallization/Glaze Spray must not be used.

– Both Speed Crystallization and Crystallization/Glaze are not suitable for the crystallization of IPS e.max CAD MO.

Notes on cooling:

– Remove IPS e.max CAD objects from the furnace after completion of the firing cycle (wait for the acoustic signal of the

furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– Do not blast or quench the objects.