Optional – Ivoclar Vivadent IPS e.max CAD Chairside v.1 Benutzerhandbuch

Seite 88

36

Optional

Adjustments with IPS e.max CAD Crystall./Add-On

For minor shape adjustments (e.g. proximal or occlusal contact points), IPS e.max CAD Crystall./Add-On is

available . The adjustments may be made with both Crystallization/Glaze and Corrective firing.

Processing:

– Mix IPS e.max CAD Crystall/Add-On with IPS e.max CAD Crystall/Add-On Liquid to an easy-to-contour

consistency.

– Ensure even mixing of the add-on material and the liquid in order to achieve an optimum firing result.

– Apply the mixed add-on material directly on the unfired Glaze Paste and/or Shades and Stains in the areas to be

adjusted and fire.

– If the Glaze Spray is used, apply the Shades and Stains first. Subsequently, supplement the missing areas using Add-On.

Apply the Glaze Spray immediately after the application of the Add-On and fire.

– Conduct the Combination firing (crystallization/glaze HT/LT) after the application of Add-On on the «blue», non-

crystallized restoration.

– Conduct the Corrective firing if Add-On is applied on an already crystallized restoration.

– Speed Crystallization/Glaze Spray must not be used in conjunction with the Add-On.

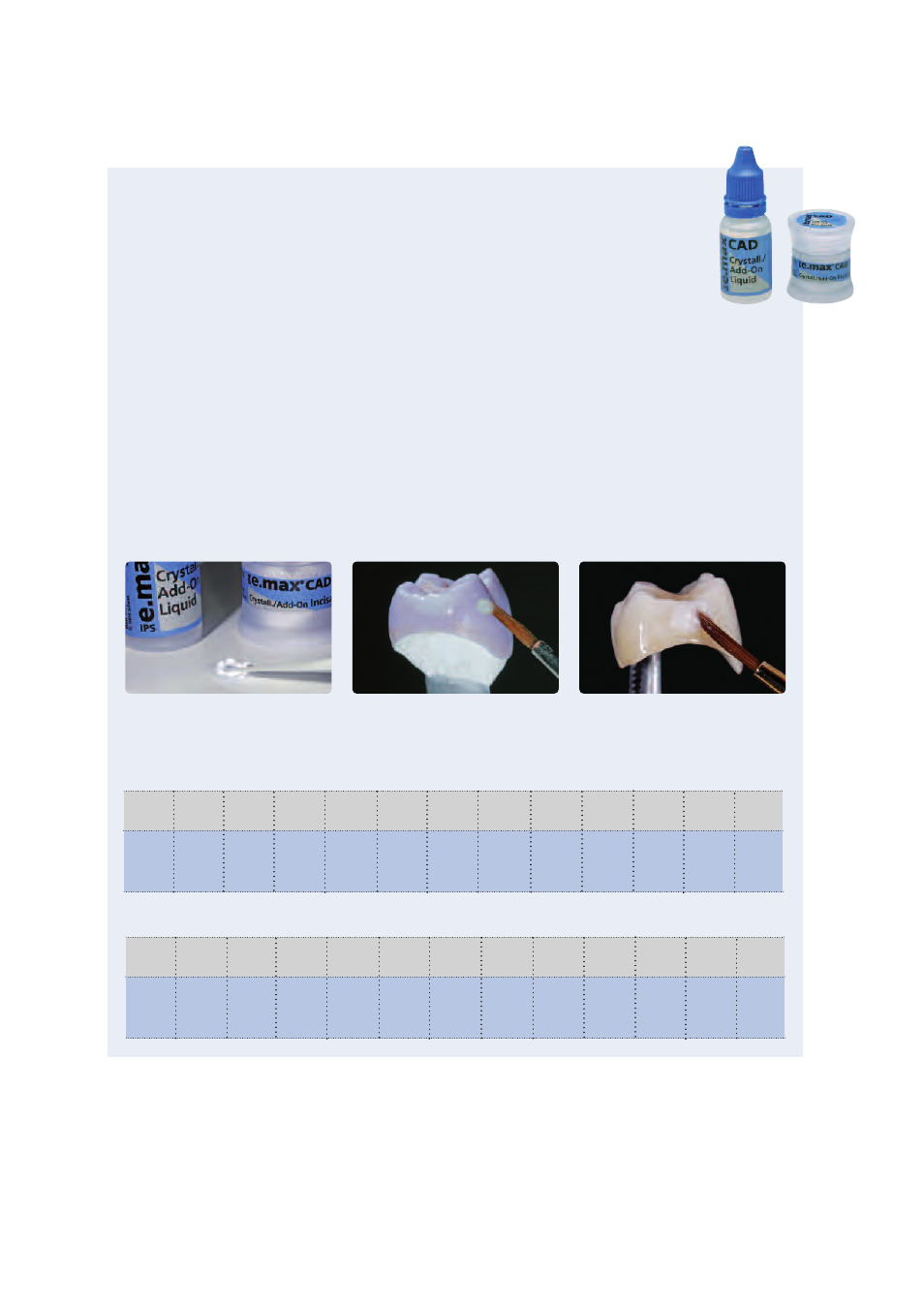

Mix IPS e.max CAD Crystall/Add-On with IPS e.max CAD

Crystall/Add-On Liquid to an easy-to-contour consistency.

Application of the mixed Add-On on the blue restoration

before crystallization

Application of the mixed Add-On on the crystallized restora-

tion

Firing parameters for the Corrective firing

Furnace

Programat

CS

Program 2

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

6:00

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding

time

H

1

[min]

0:10

Heating rate

t

2

[°C/°Fmin]

30/54

Firing

temperature

T

2

[°C]

840/1544

Holding

time

H

2

[min]

7:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C/°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0

Firing parameters Crystallization / Glaze HT/LT

Furnace

Programat

CS

Program 1

Stand-by

temperature

B

[°C/°F]

403/757

Closing time

S

[min]

6:00

Heating rate

t

1

[°C/°F/min]

90/162

Firing

temperature

T

1

[°C/°F]

820/1508

Holding

time

H

1

[min]

0:10

Heating rate

t

2

[°C/°Fmin]

30/54

Firing

temperature

T

2

[°C]

840/1544

Holding

time

H

2

[min]

7:00

Vacuum 1

1

1

[°C/°F]

1

2

[°C/°F]

550/820

1022/1508

Vacuum 2

2

1

[°C/°F]

2

2

[°C/°F]

820/840

1508/1544

Long-term

cooling

L

[°C/°F]

700/1292

Cooling rate

t

l

[°C/°F/min]

0